You might think that foam has a very limited role in our life. But this isn’t true. The upholstery foam is crucial in various projects, from furniture refurbishment to DIY crafting. The comfy sofas that we enjoy spending time on, along with the custom seat cushions or working on a creative project, all require upholstery foam in order to achieve professional results.

However, cutting upholstery foam for creative purposes can be tricky as it is difficult to penetrate a sharp object into the soft, squishy, and spongy surface. With the right methods and tools, you can achieve the desired cutting of the upholstery foam. Moreover, you also need to choose the type of foam according to your need and as different material requires different type of foam.

In this article, we will solve your query and clarify how to cut upholstery foam. Do keep reading to know everything in detail.

What is an Upholstery Foam?

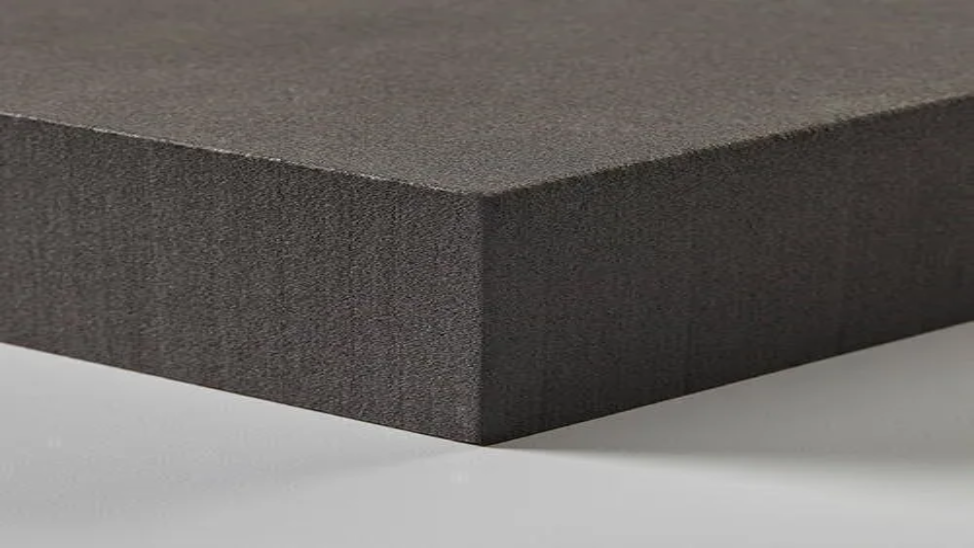

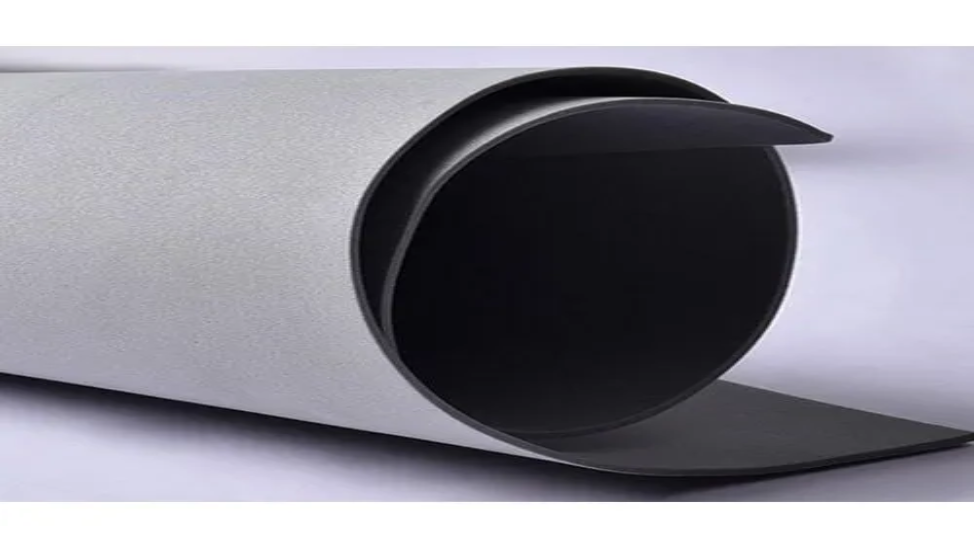

Before we get started, it is necessary for you to know about the product in detail. Upholstery foam is a specialized type of foam used in the furniture and upholstery industry to provide comfort, support, and aesthetic appeal to various seating and cushioning applications.

It is typically made from polyurethane, a versatile material known for its resilience and cushioning properties. Upholstery foam comes in various densities, determining its support level and firmness. Low-density foams are softer and more suitable for seatbacks and cushions, while higher-density foams provide firmer support and are often used in seat cushions and mattresses.

Additionally, upholstery foam is available in different thicknesses to accommodate various furniture and cushion designs. Thus, it is highly necessary to cut these foam sheets in order to place them in furniture-related things.

Similar Post: 15 Backyard Deck Ideas on a Budget to Upgrade Your Deck’s Look

Material Required to Cut Upholstery Foam

In order to cut the upholstery foam precisely, you will require some tools. You can easily get these materials near your hardware store or online. The list is mentioned below; make sure to collect them all before you get started.

- Upholstery foam

- Measuring tape or ruler

- Marker or pen

- Utility knife or electric knife

- Cutting mat or cardboard

Steps for Cutting Upholstery Foam

Cutting the upholstery foam requires some steps to make your work easier. In order to have a clean and safe design with the upholstery foam, you need to follow all the steps appropriately.

1. Choose a Right blade

The most important step is to choose the right blade. There are so many blades available in the market, and you need to keep a few things in mind in order to have a safe and clean cutting of the upholstery foam.

- Ensure the blade is sharp to achieve clean and effortless cuts. Dull blades may lead to uneven edges and may require more force.

- Opt for a blade that is long enough to cut through the thickness of the foam in a single pass.

- A utility knife with a retractable blade allows you to control the blade’s exposure, reducing the risk of accidental cuts and enhancing safety during storage.

- Choose a sturdy blade that is not too flimsy, as foam can sometimes require a bit of pressure to cut through, especially if it’s high-density foam.

- A straight-edge blade is generally sufficient for most upholstery foam-cutting tasks.

These were some important points before choosing the blade to cut the foam. However, there are several types of upholstery foam available in the market. We have mentioned some of them that are best suited for cutting the upholstery foam properly.

Best Blades to Cut Upholstery Foam

- Straight Utility Knife Blade: This is the most commonly used knife blade for cutting upholstery foam, and it provides a sharp edge suitable for most foam-cutting tasks. However, you need to look at whether the blade is sharp in order to achieve clean and precise cuts.

- Hook Blade: Yes, it is similar to captain hook’s hand as this blade has a curved shape, resembling a hook or a half-circle. Moreover, this blade type is best used for cutting thicker foam or making curved or rounded cuts. While cutting the dense foams, this blade helps to have better control in comparison to other foams.

- Electric Knife Blade: This is a helping hand for people who have to cut bundles of large or thick pieces of upholstery foam. For this purpose, an electric knife with a serrated blade can be highly effective. The electric knife’s vibration and serrated edge make cutting through denser foam materials easier.

- Foam Saw Blade: As the name suggests, these foam saw blade is specially designed for cutting foams. These blades have teeth that are more widely spaced apart, reducing friction and ensuring a cleaner cut through the foam. They are commonly used for precision cutting and crafting foam shapes.

- Rotary Cutter Blade: Rotary cutters are primarily used in quilting and crafting but can also be used to cut upholstery foam. The rotary cutter blade is circular and sharp, allowing for smooth and precise cuts along straight or curved lines.

These common options work well for cutting foams of different varieties. However, there are so many options available in the market. Choose the safe and the most relevant option that is suitable for you.

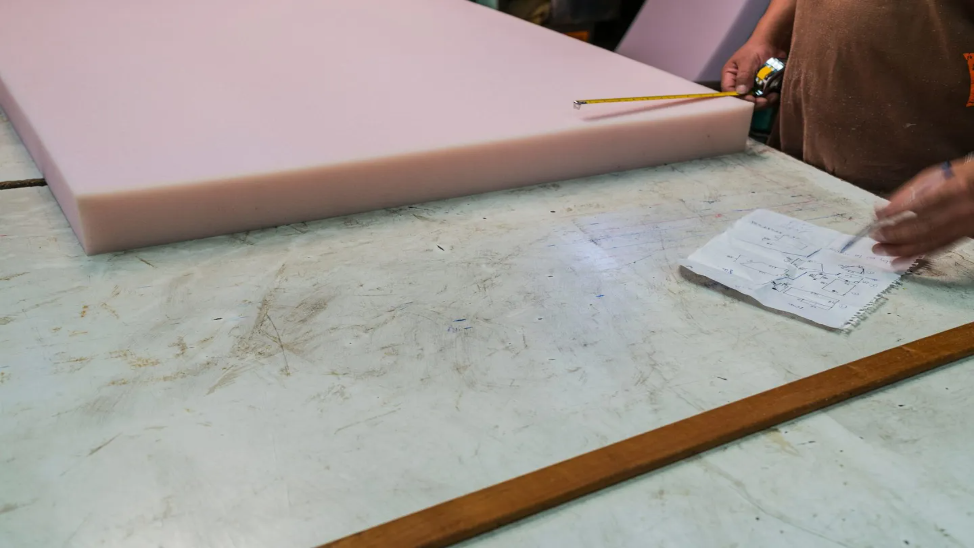

2. Measurement and Markings

Accurate measurement and markings are crucial when cutting upholstery foam to ensure precise and well-fitted pieces for your project. Before you begin cutting, take precise measurements of the foam using a measuring tape or ruler. Mark the dimensions on the foam’s surface with a marker or pen, ensuring the lines are straight and clear.

Use a ruler or straight edge to guide your cutting tool along the marked lines for straight cuts. If your project requires angled cuts or complex shapes, consider creating a paper or cardboard template first, which can then be traced onto the foam before cutting. Taking your time to measure and mark correctly will help you achieve the desired size and shape, leading to a professional and polished finish in your upholstery foam project.

Always remember to prioritize safety while handling cutting tools and protect your work surface to avoid any damage or accidents during the cutting process.

3. Prepare the Area for Cutting the Foam

First and foremost, find a well-lit and spacious work surface with enough room to accommodate the foam’s size and the cutting tools. Lay down a cutting mat or a thick piece of cardboard underneath the foam to protect the surface from any potential damage caused by the cutting tool.

This prevents scratches on your work surface and allows for easier and smoother cutting. Additionally, ensure that the foam is secure and stable in the work area to avoid any unnecessary movements during the cutting process. A non-slip surface or using clamps to hold the foam in place can be helpful in this regard.

Lastly, ensure that all your cutting tools, such as the utility knife or electric knife, are in good condition and within reach.

4. Cut the Upholstery Foam

To cut the upholstery foam properly, follow the precise markings made earlier and use the appropriate cutting tool for the task. If using a utility knife, make sure the blade is sharp and apply consistent pressure along the marked lines. Take your time to ensure even and smooth cuts, avoiding rushing the process to maintain accuracy.

For thicker foam or more intricate shapes, a hook blade or electric knife with a serrated edge can be beneficial. Carefully guide the tool along the marked lines, ensuring a steady hand and maintaining control throughout the cutting process. If necessary, make multiple passes to achieve the desired depth for thicker foam.

Regularly check the cut edges to ensure they are clean and even. Trim any uneven areas or excess foam if needed.

5. Cut the Upholstery Foam at The Right Angle

As mentioned above, these foams are used for furniture-related things and cushions to provide extra comfort. Thus, at times it is necessary to cut these upholstery foams at a right angle. Also, cutting upholstery foam at the right angle is essential to achieve precise and professional results in your projects.

Before making any cuts, ensure that you have measured and marked the angles accurately on the foam’s surface using a ruler or protractor. Use a straightedge to guide your cutting tool along the marked line for straight cuts, maintaining a consistent angle. If your project requires angled cuts, such as for seat cushions or custom shapes, take your time to ensure the angles are correctly marked and aligned.

It’s crucial to maintain a steady hand and use a sharp cutting tool when cutting at an angle.

6. Take a Look at The Cuts

In order to receive a precise and professional cut on the upholstery foam, it is necessary to look at the cuts that you have made. Once you have completed the cutting process, inspect the edges of the foam to ensure they are clean and even.

In order to have a proper view, keep the foam on a steady and slightly up surface once you have observed every single cut cleanly. Then you should trim any uneven areas, if necessary, using the cutting tool. This is an important step in order to achieve a professional and polished finish look.

Once you are done with the inspection, you can store the leftover foam for filling the cushion as they can form a small cushion for your home purpose.

Different Types of Foam

Foam is a versatile material and is used in various industries, whether it is furniture, manufacturing, packaging, or insulation. The possibility is endless. However, we have mentioned some types of foam other than upholstery foam for your reference.

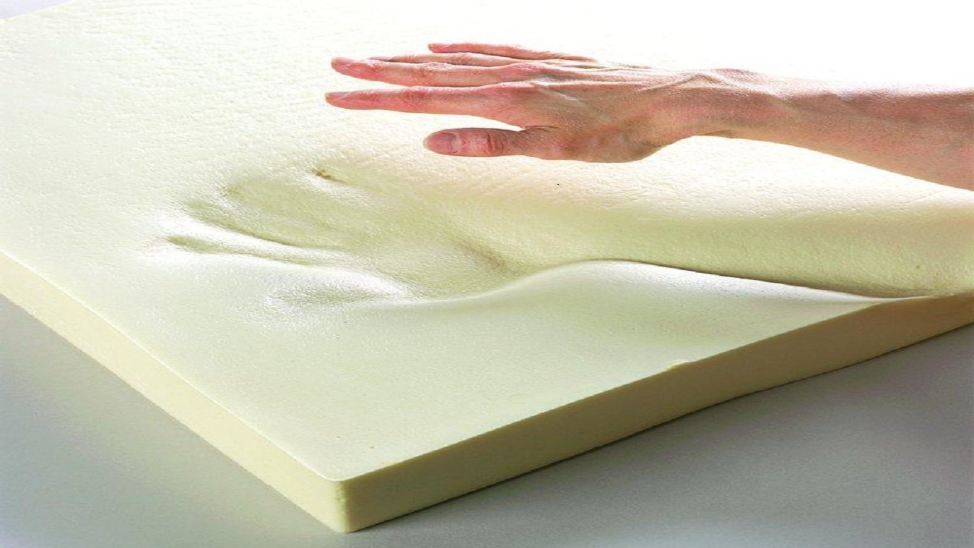

1. Memory Foam

Also known as viscoelastic foam, Memory foam is a type of polyurethane foam with added chemicals to increase its viscosity and density. This foam reacts to body heat and pressure, conforming to the shape of the body and evenly distributing weight. It is widely used in mattresses, pillows, and medical applications to alleviate pressure points and improve comfort.

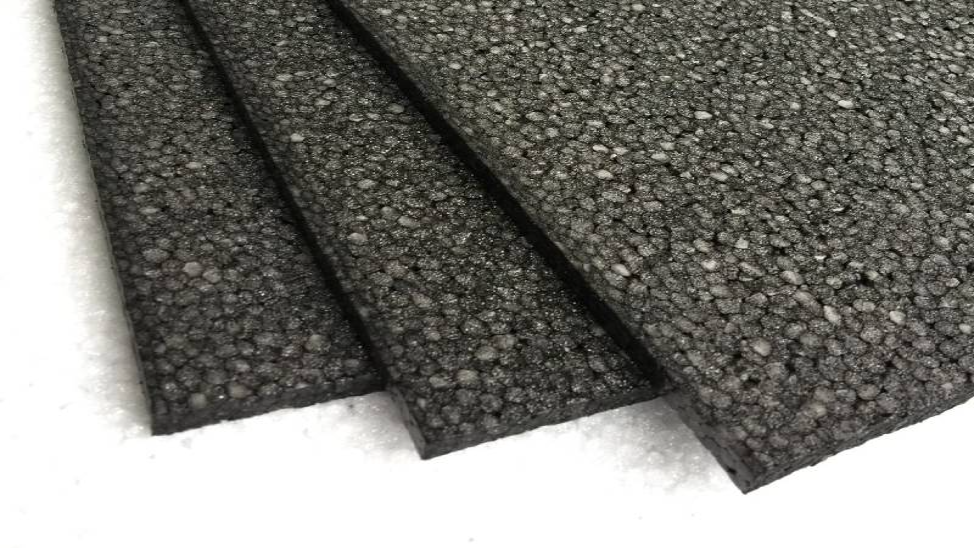

2. Polystyrene Foam (EPS and XPS Foam)

Polystyrene foam comes in two main types: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). EPS foam is lightweight and has excellent insulation properties, making it suitable for packaging, building insulation, and craft projects. XPS foam is denser and more water-resistant, often used for thermal insulation in buildings and as a core material in some composite structures.

Also Read: Top 9 Brick Fire Pit DIY Designs for Your Backyard

3. Polyethylene Foam (PE Foam)

Polyethylene foam is a closed-cell foam known for its durability, water resistance, and buoyancy. It is used in various applications, including protective packaging for delicate items, sports equipment padding, and water sports flotation devices.

4. Polypropylene Foam (PP Foam)

Polypropylene foam is a lightweight, closed-cell foam with good impact resistance and chemical stability. It is commonly used in the automotive industry for components like bumper cores, door panels, and seat structures.

5. Neoprene Foam

Neoprene foam is a type of synthetic rubber foam with excellent resistance to oil, chemicals, and weathering. It is commonly used in gaskets and seals and as padding in wetsuits and other water-resistant products.

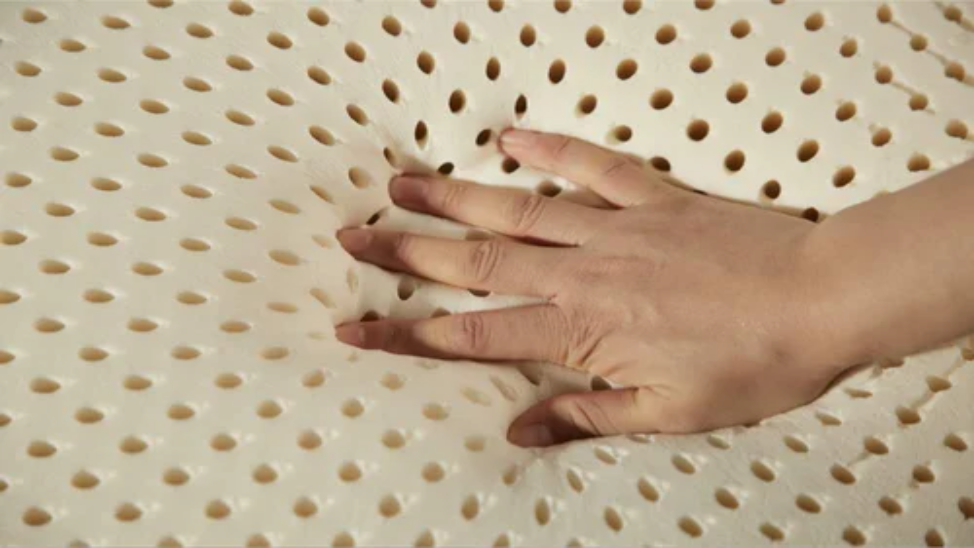

6. Latex Foam

Latex foam is made from natural or synthetic latex rubber. It is known for its resilience, breathability, and anti-microbial properties. Latex foam is used in mattresses, pillows, and upholstery.

See More: How to Add and Install Kitchen Banquette Seating

7. EVA Foam (Ethylene-Vinyl Acetate)

EVA foam is a lightweight, closed-cell foam with excellent shock absorption properties. It is commonly used in sports equipment, shoe insoles, children’s play mats, and various craft projects. Moreover, they are on a softer side than other foams available in the market.

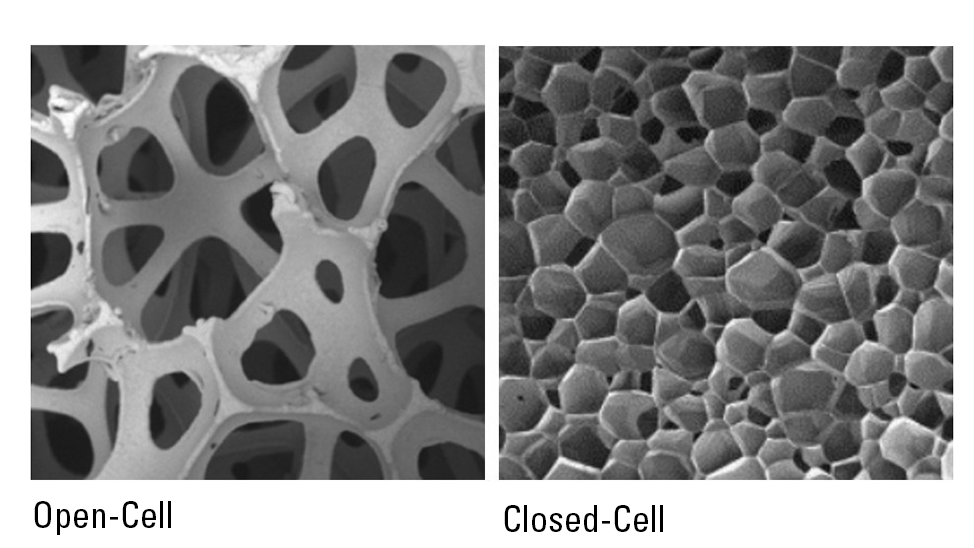

8. Closed-Cell vs. Open-Cell Foam

Foams can also be classified as closed-cell or open-cell based on their structure. Closed-cell foams have sealed cells, making them more water-resistant and providing better insulation. Open-cell foams have interconnected cells, which allow air and moisture to pass through, making them more breathable and softer.

As mentioned, every foam has unique characteristics, making them suitable for various applications across different industries. You can choose the foam according to your need, and the cost of every foam is different according to its purpose.

Related: DIY Antiqued Mirror: A Basic Guide

Conclusion

Cutting upholstery foam seems like a simple task, but precision and accuracy are very important in order to execute this task cleanly. However, we have precisely mentioned the step-by-step process of cutting the upholstery foam. If you are cutting foam at your home, then be sure you are doing it in solitude.

This is because kids can reach a sharp knife or object and can harm themselves. Therefore, remember to prioritize the safety of yourself and your family members. Always exercise caution while using any cutting tool and ensure you have a firm grip on the utility knife to avoid accidents. Additionally, consider using a cutting mat or a protective surface underneath the foam to protect your work area and improve cutting precision.

Whether you’re reupholstering furniture or creating custom foam cushions, mastering the art of cutting upholstery foam will elevate your DIY projects and leave you with impressive, professional-looking results.

Check This Next: DIY Spackle Art: How to Create Your Own Abstract Art